Ultem material is a high-performance thermoplastic that has become increasingly popular in the manufacturing industry. One of its most significant benefits is its compatibility with 3D printing. In this blog post, we’ll explore why Ultem material is ideal for 3D printing and how Salco Engineering & Manufacturing can help you leverage this material for your manufacturing needs.

What is Ultem Material?

Ultem is a type of thermoplastic that is commonly used in manufacturing. It is a member of the polyetherimide (PEI) family of polymers and is known for its high strength, durability, and resistance to heat and chemicals. Ultem material is commonly used in the aerospace, automotive, and medical industries due to its excellent mechanical properties.

Why is Ultem Ideal for 3D Printing?

Ultem material is an ideal choice for 3D printing due to its high strength and durability. It is also resistant to high temperatures and chemicals, making it suitable for a wide range of applications. In addition, Ultem material is known for its excellent dimensional stability, which is essential in 3D printing.

One of the most significant advantages of Ultem material in 3D printing is its ability to produce high-quality parts with exceptional accuracy. This material has a low coefficient of thermal expansion, which means that the parts produced with Ultem material have minimal distortion and shrinkage.

Applications of Ultem Material in 3D Printing

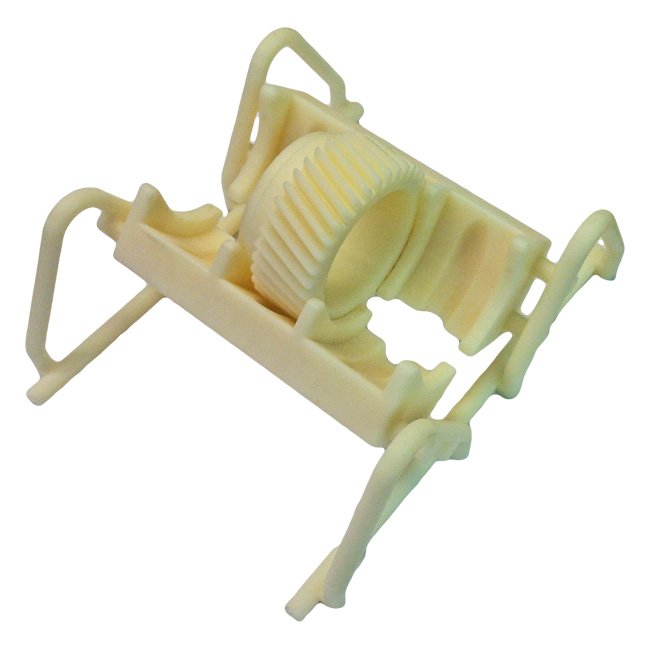

Ultem material is ideal for a wide range of applications in 3D printing. Its excellent mechanical properties make it suitable for producing functional prototypes and end-use parts for the aerospace, automotive, and medical industries. It is also an excellent choice for producing parts that require high strength and durability, such as gears, housings, and brackets.

Ultem is also widely used in the production of jigs and fixtures for manufacturing processes. These parts are used to hold workpieces in place during machining, assembly, and inspection processes. Ultem is an ideal choice for jigs and fixtures due to its high strength, durability, and dimensional stability.

How Salco Engineering & Manufacturing Can Help

Salco Engineering & Manufacturing is a leading provider of custom manufacturing solutions. We specialize in 3D printing and have extensive experience working with Ultem material. Our team of experts can help you leverage this material for your manufacturing needs, whether it be for prototyping, end-use parts, or jigs and fixtures.

We use the latest 3D printing technology to produce high-quality parts with exceptional accuracy. Our state-of-the-art 3D printers can produce parts with complex geometries and intricate details. We can also produce parts in various sizes, from small to large.

At Salco Engineering & Manufacturing, we pride ourselves on delivering high-quality parts on time and within budget. We work closely with our clients to understand their specific needs and provide them with customized solutions that meet their requirements. We also offer competitive pricing and fast turnaround times to ensure that our clients receive the best value for their investment.

Conclusion

In conclusion, Ultem is an ideal choice for 3D printing due to its high strength, durability, and resistance to heat and chemicals. Its excellent dimensional stability and low coefficient of thermal expansion make it an ideal choice for producing high-quality parts with exceptional accuracy. Salco Engineering & Manufacturing can help you leverage Ultem material for your manufacturing needs, whether it be for prototyping, end-use parts, or jigs and fixtures. Contact us today to learn more about how we can help you achieve your manufacturing goals.