Design and prototyping are crucial stages in the manufacturing process. They allow companies to test and refine their products before mass production, reducing the risk of costly errors and delays. The design stage involves creating a detailed plan for the product, including its functionality, appearance, and materials. Prototyping involves creating a physical model of the product, allowing designers to test its performance and identify any design flaws.

Design and prototyping are particularly important for complex products, as they allow designers to identify and correct any issues before production begins. By testing the product in the prototyping phase, companies can ensure that the final product meets their specifications and is of high quality.

Design Services Offered by Salco Engineering

Salco Engineering offers a range of design services to its clients. Our team of experienced designers can work with clients to create detailed plans for their products, including their functionality, appearance, and materials. We use the latest SolidWorks software and design tools to create 3D models of products, allowing clients to see a virtual representation of the final product.

Our design services include product design, tool design, and engineering analysis. Our product design services involve creating detailed plans for new products or improving the design of existing products. Our tool design services involve creating the tools and molds needed for mass production. Our engineering analysis services involve testing the product design to ensure that it meets the client’s requirements and specifications.

Prototyping Services Offered by Salco Engineering

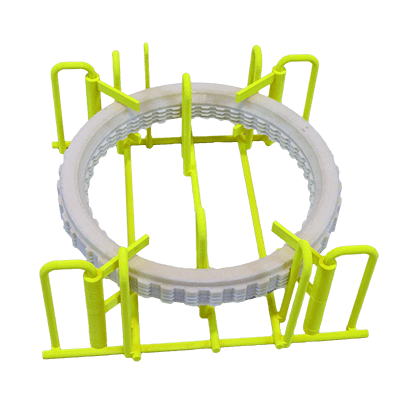

Salco Engineering also offers a range of prototyping services to its clients. Our team of experts can create physical models of products, allowing clients to test their performance and identify any design flaws. We use a variety of techniques to create prototypes, including 3D printing, CNC machining, and injection molding.

Our prototyping services include rapid prototyping, functional prototyping, and pre-production prototyping. Our rapid prototyping services involve creating quick and inexpensive prototypes, allowing clients to test their design ideas and make changes as necessary. Our functional prototyping services involve creating prototypes that accurately represent the final product, allowing clients to test their performance and functionality. Our pre-production prototyping services involve creating a small batch of prototypes that are identical to the final product, allowing clients to test their performance in a real-world environment.

Benefits of Using Salco Engineering for Design and Prototyping

By using Salco Engineering for design and prototyping, clients can benefit from our expertise and experience in the field. Our team of designers and engineers has years of experience in creating and testing products for a wide range of industries, including automotive, aerospace, medical, and consumer products.

Our design and prototyping services can help clients to reduce the risk of errors and delays in the manufacturing process, ensuring that their products are of high quality and meet their specifications. By testing the product in the prototyping phase, clients can identify any design flaws and make changes as necessary, reducing the risk of costly errors during mass production.

Conclusion

Design and prototyping are essential components of the manufacturing process, allowing companies to create and test products before investing in mass production. Salco Engineering offers a range of design and prototyping services to its clients, including product design, tool design, rapid prototyping, functional prototyping, and pre-production prototyping. By using our expertise and experience in the field, clients can benefit from reduced risk, improved quality, and cost savings in the manufacturing process. Contact us today.