Wire Forming

At Salco Engineering, we specialize in delivering top-tier wire forming services tailored to meet the specific needs of our clients. Whether you require simple or complex wire forms, our advanced CNC wire forming capabilities ensure precision, accuracy, and unparalleled quality in every project. With our Numalliance FTX10 3D bending machine, we are equipped to produce intricate wire forms that align perfectly with your design specifications, no matter how demanding they may be.

Custom Wire Forming with State-of-the-Art Technology

Our custom wire form services are designed to cater to the unique requirements of each client. Our CNC wire bender allows us to create intricate wire shapes with consistent precision. This advanced machinery can handle a wide range of wire diameters, offering versatility and flexibility for various applications. Whether you are in the industrial, automotive, aerospace, or another sector, our custom wire forming solutions are crafted to meet your exact needs.

CNC Wire Forming Capabilities

Salco’s CNC wire forming services are distinguished by their precision and reliability. Our CNC machine features seven digital axes, enabling us to execute complex wire bends with remarkable accuracy. Key features of our wire forming services include:

- Wire Diameter Range: Capable of handling wire sizes from 0.1205″ to 0.625″, accommodating a variety of project needs.

- 3D Wire Bending: Advanced 3D wire bending directly from coil ensures each form is made with minimal waste and maximum efficiency.

- Double Bend Capability: Our equipment allows for double bends in a single operation, enhancing productivity.

- Multiple Radii Bending: The machine’s bending head can produce multiple radii, offering flexibility in design.

- Single Minute Exchange Tooling: Rapid tooling changes minimize downtime, allowing for quick turnaround times.

- Tensile Strength Handling: Our equipment manages wire with tensile strengths up to 600 N/mm2 (85 Ksi), making it suitable for demanding applications.

- Arm Length and Bending Pin Race: The bending arm length ranges from 1,045 to 1,210 mm (41.14-47.63”), with a bending pin race of 60mm (2.4”).

Why Choose Salco Engineering for Your Wire Forming Needs?

Choosing Salco Engineering means partnering with a company that prioritizes precision, customization, and quality. Our CNC wire forming services are not just about meeting specifications—they’re about exceeding them. We understand that every project is unique, which is why we offer custom wire forming solutions that are tailored to your specific requirements.

Our experienced design team is ready to collaborate with you to develop wire forms that meet your exact needs. We bring extensive industry knowledge and a commitment to innovation to every project, ensuring that our wire forming services not only meet but surpass your expectations.

Explore Our Wire Forming Expertise

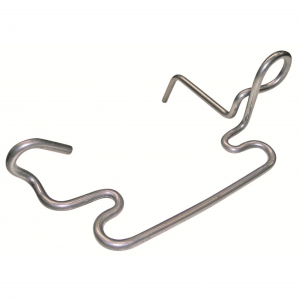

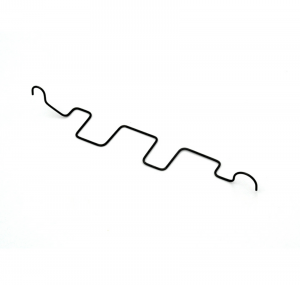

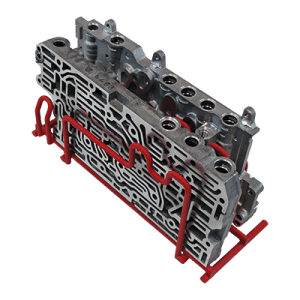

At Salco Engineering, we take pride in showcasing the exceptional capabilities of our CNC wire bending services. Whether you’re looking for inspiration or want to see the quality of our work firsthand, we invite you to explore examples of our wire forming projects in our gallery below.

Request a Quote for Custom Wire Forming

Ready to start your next wire forming project? Contact Salco Engineering today to request a free quote. We’re dedicated to providing high-quality custom wire forming services at competitive prices and look forward to helping you achieve your project goals with precision and efficiency.

By choosing Salco for your wire forming needs, you’re investing in a partner committed to delivering the best in CNC wire bending technology and custom solutions that fit your unique requirements. Let us help you bring your wire forming projects to life with unparalleled accuracy and quality.

Ready for a Quote?

Salco can quote wire forming projects of all shapes and sizes. If you have questions about our services, please click here to contact us. Someone from our team will be happy to assist you.

Related Products & Services

Our specialized baskets can be made with wire dividers, holders, frames, or custom part holding features.

The best of both worlds. Wire inserts are made to fit your particular part and placed in standard plastic dunnage.

Complex design work using SolidWorks, 3D printing, and physical prototyping for all types of projects.

Custom bakery racks with casters, product shopping displays, and end racks are available in all shapes and sizes.