Design and Prototyping

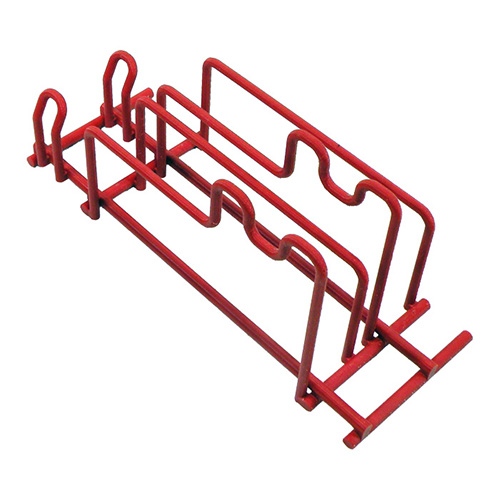

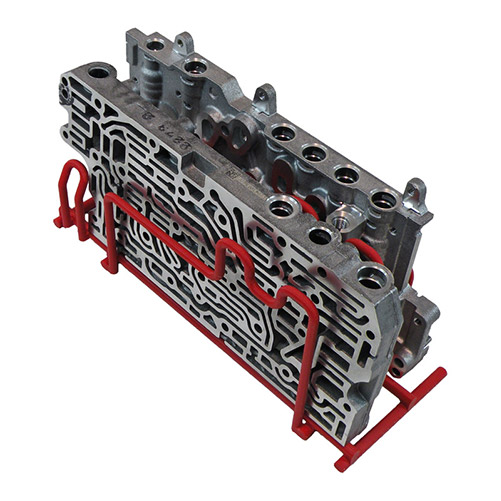

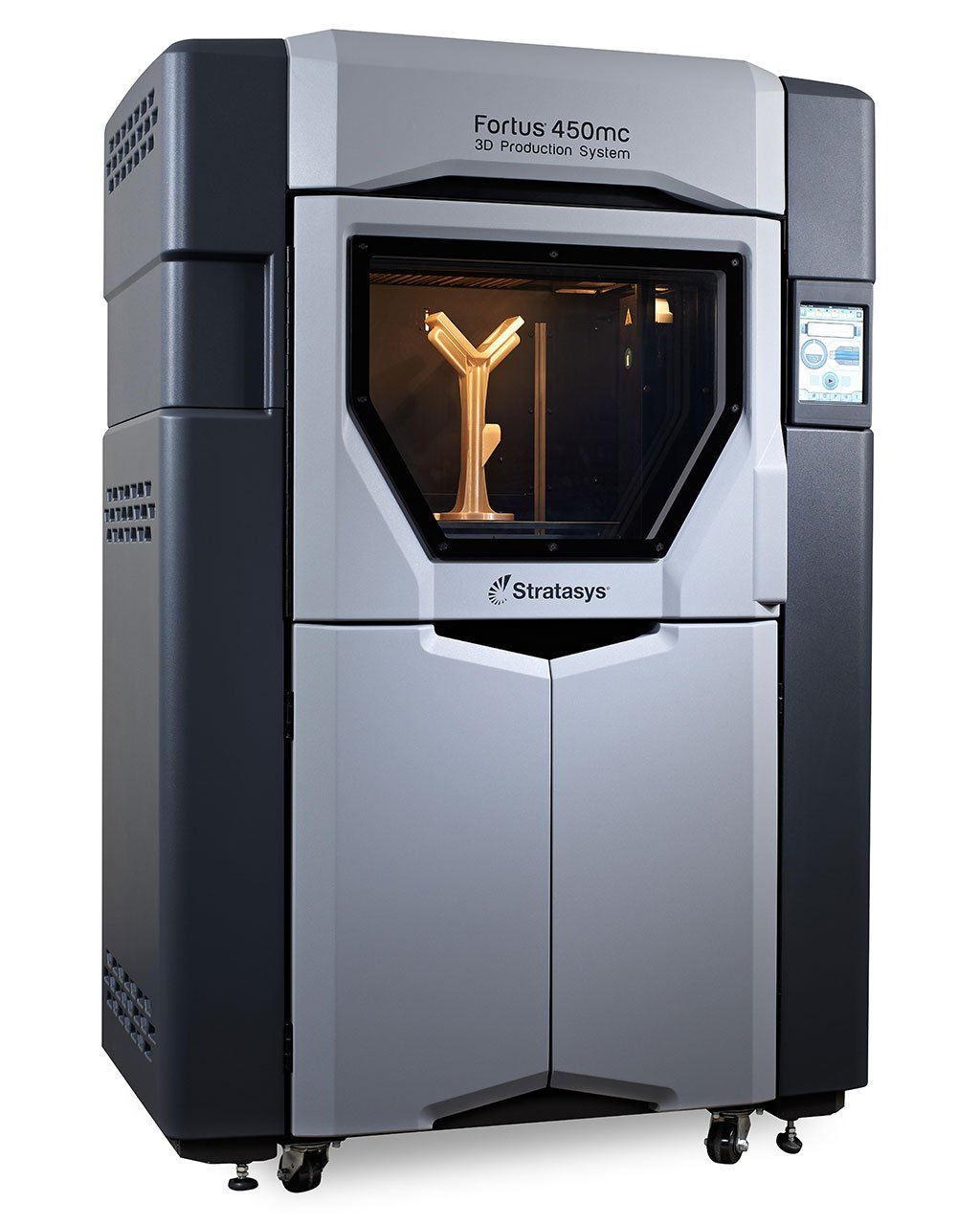

Salco specializes in complex design work and prototyping for all types of projects, with the ability to quickly build physical samples for customer approval. Salco uses SolidWorks software for design and a Stratasys Fortus 450mc for 3D printing. We have the ability to print in high temp ULTEM material, which is ideal for quick turnaround tooling. Our many years of experience promises craftsmanship and care for all of our projects.

Maximum Part Size

The Stratasys 450mc 3D printer has a maximum build area of 16 x 14 x 16 inches (406 x 356 x 406 mm). Larger parts can be printed in multiple pieces and assembled.

Material Options

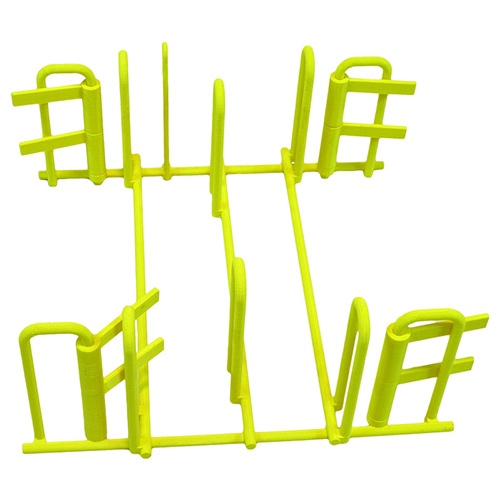

Salco’s 3D printer can print in a variety of materials including ULTEM 1010, Nylon 12, and ASA.

- ULTEM 1010: A high-performance polyetherimide (PEI) thermoplastic. The high heat resistance makes ULTEM a perfect material for making welding jigs and fixtures.

- Nylon 12: The strength, toughness, and excellent fatigue properties of Nylon 12 make it a perfect fit for applications involving snap-fit closures, tools with press-fit inserts, and vibration-resistant parts.

- ASA: Acrylonitrile Styrene Acrylate is the perfect all-purpose 3D printing thermoplastic, suitable for many different applications. It has a similar chemical makeup to ABS plastic but offers three improvements: better mechanical properties, superior aesthetics and it’s UV resistant. ASA material also comes in 10 colors, more than any other FDM material.

Ready for a Quote?

Salco can quote projects of all shapes and sizes. If you have questions about our services, please click here to contact us. Someone from our team will be happy to assist you.

Design and Prototyping Process

Salco Engineering and Manufacturing works closely with clients to understand their specific needs and requirements. The company’s experienced team of engineers uses the latest design software to create 3D models of the client’s product. These models are then used to create prototypes using the Fortus 450mc 3D Printer or other prototyping methods.

Benefits of Design and Prototyping Services

Working with Salco Engineering and Manufacturing for design and prototyping services can provide clients with numerous benefits. The use of rapid prototyping enables clients to test their products before final production, reducing the risk of errors and saving time and money. The company’s experienced team can also provide valuable feedback and suggestions for design improvements.