CNC Milling

Precision CNC Milling for Diverse Industries

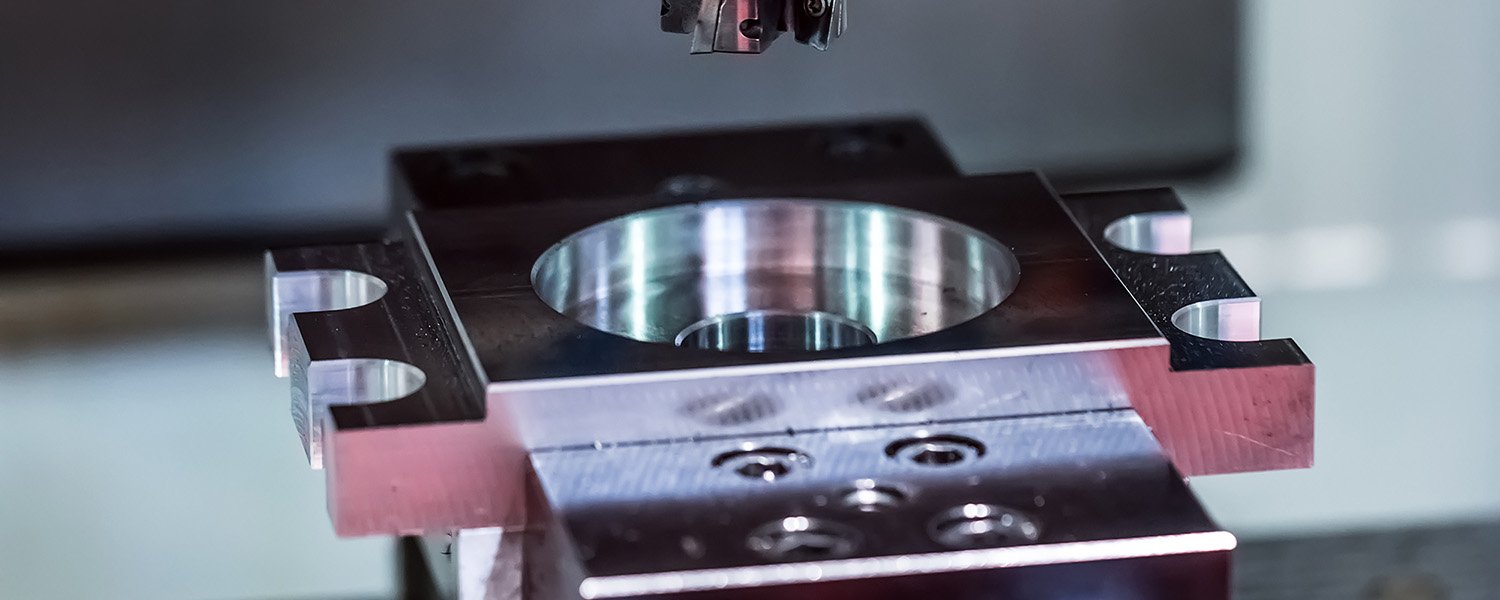

At Salco, we offer state-of-the-art CNC milling services that cater to a wide range of industries. Our precision milling capabilities allow us to produce complex parts with tight tolerances, ensuring high-quality results for every project. Whether you are in the automotive, aerospace, medical, or electronics industry, our CNC milling services are designed to meet your specific needs with unparalleled accuracy and efficiency.

Advanced CNC Milling Technology

Our facility is equipped with the latest CNC milling machines, which are capable of handling a variety of materials, including aluminum, steel, titanium, and plastics. By utilizing advanced software and cutting-edge technology, we can create intricate designs and detailed components that meet the exact specifications of our clients. Our skilled technicians have extensive experience in CNC milling, ensuring that each project is completed to the highest standards of quality and precision.

Custom Milling Solutions

Salco understands that each client has unique requirements, which is why we offer customized CNC milling solutions tailored to your specific needs. From prototyping to full-scale production, we provide comprehensive support throughout the entire manufacturing process. Our team works closely with you to develop prototypes, refine designs, and produce high-quality parts that meet your exact specifications. With our custom CNC milling services, you can be confident that your project will be completed on time and within budget.

Quality and Customer Satisfaction

Quality is at the core of our CNC milling services. We implement rigorous quality control measures at every stage of production to ensure that each part meets the highest standards of precision and durability. Our commitment to customer satisfaction drives us to deliver exceptional results and build lasting relationships with our clients. By choosing Salco Engineering for your CNC milling needs, you are partnering with a team that is dedicated to excellence and innovation.

Ready for a Quote?

Salco can quote projects of all shapes and sizes. If you have questions about our services, please click here to contact us. Someone from our team will be happy to assist you.

Salco offers custom milling services using our Fryer MB-16R. Request a quote today. The Fryer MB-16R milling machine is a versatile and reliable machine designed to meet the needs of modern machining applications. It offers a wide range of features and capabilities that make it suitable for use in various industries, including aerospace, automotive, and medical.

Salco offers custom milling services using our Fryer MB-16R. Request a quote today. The Fryer MB-16R milling machine is a versatile and reliable machine designed to meet the needs of modern machining applications. It offers a wide range of features and capabilities that make it suitable for use in various industries, including aerospace, automotive, and medical.

The Fryer MB-16R milling machine features a powerful spindle motor that delivers high torque and speed. This makes it suitable for machining a wide range of materials, including steel, aluminum, and titanium. It also has a high-speed tool changer, which allows for rapid tool changes, saving time and increasing productivity.

In addition to its excellent construction and powerful spindle motor, the Fryer features the latest generation Siemens 828D CNC control, which offers advanced features such as conversational programming and high-speed machining. This makes it easy for operators to set up and operate the machine, resulting in increased productivity and efficiency.

The Fryer MB-16R milling machine is a reliable, high-performance machine that is suitable for a wide range of machining applications. Its rigid construction, powerful spindle motor, and user-friendly control system make it a popular choice for industries such as aerospace, automotive, and medical. If you are looking for high-quality milling services, get in touch with Salco for a quote.

Machine Capacity

- X Travel – 60″

- Y Travel – 25″

- Z Travel – 24″

- Table Load – 2950 lbs

- Ballscrew Size – 1.57″

- Table Size – 18″ x 70″

- T-Slots (No. / Width) – 5 / 0.630″

- Table Top to Floor – 36″

Spindle

- Motor (Peak) – 12 HP

- Max Spindle Torque – 40 ft/lbs

- Spindle Speeds – 60 – 80000 RPM

- Tool Type / Taper – CAT 40 (BT-40 Optional)

- Spindle Nose to Table (Max – Min) – 28″ – 4″

- Spindle Center to Column – 25″

ATC

- Tool Storage Capacity – 12 (20 optional)

- Tool Change Time – 7 seconds

- Tool Selection – Bi-Directional

- Max Adjacent Tool Diameter – 5.5″

- Max Tool Weight – 15.4 lbs

- Max Tool Length – 11.8″

Performance

- Positioning Accuracy – +/- 0.0002″

- Positioning Repeatability – +/- 0.001″

- Rapid Traverse – 400 IPM

- Cutting Feed Rate – 0.001 – 300 IPM

- Axis Thrust (Peak) – 4400 lbs