Salco Engineering and Manufacturing Co. was started in 1963 by Bob Currier, Harold Bussing and Walt Mitchner. Jim Flack began working for Salco in 1979, and eight years ago became company president. Not only has management changed since the business started 47 years ago, but the changing automotive industry has affected the business as well. The industry now requires cleaner parts made in a cleaner plant. Salco has been able to meet that requirement and has thrived during the difficult times. Shannon Maynard recently sat down with Flack and his son, David, who is an estimator with Salco, to discuss the business.Question: What does Salco Engineering and Manufacturing do?

Jim Flack: Design. Our big forte is that we go in, they give us parts and we design how they want it handled.

David Flack: We end up making an entire material handling system, whether it’s for their internal transportation or external transportation as well. We develop a system for them to have a consistent flow of product in a clean and efficient manner.

Question: What are the products you make used for?

J.F.: We do a lot with the bakery industry, food, automotive, medical. We do a lot of stainless steel products; more today than 10 years ago due to contamination issues.

Question: How are you able to service such a broad range of industries?

J.F.: It’s based on the design of their products. We do bread racks. We do trolleys. We do displays. It’s the same idea with another area of focus.

D.F.: At the end of the day, it’s still some form of a product that needs to be contained in the way the customer needs it to be contained and presented. It all works together. … A lot of it is problem solving and being able to take a broad vision and narrow it.

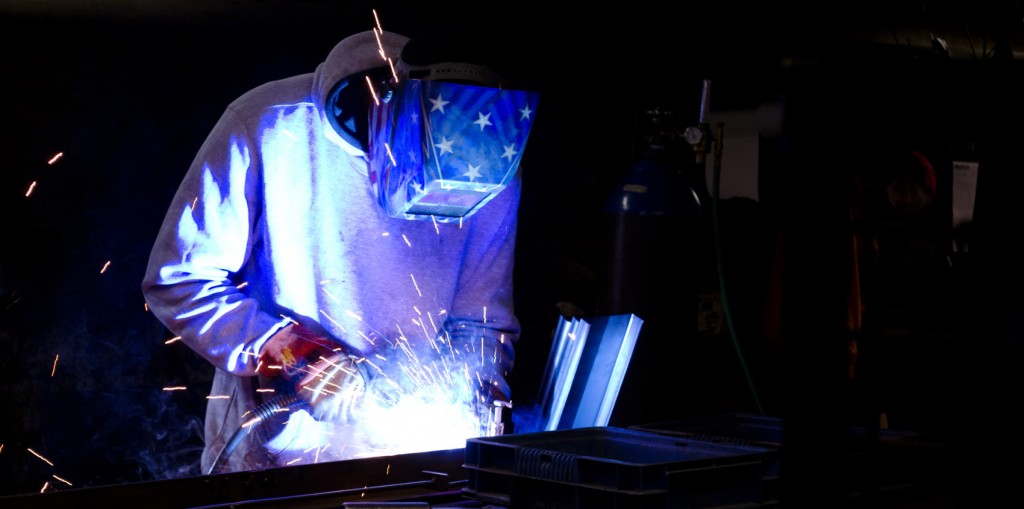

Question: What materials do you use to make your products?

J.F.: Stainless steel, basic wire and basic steel.

Question: You offer primarily custom work. Why was that important to provide your customers?

D.F.: It has to be. Anybody can go to Home Depot and buy 100 boxes to contain their product.

J.F.: It’s also a longevity issue. Our components have to last.

D.F.: It’s very durable. It is a product that lasts a long time and is completely recyclable when it doesn’t.

Question: How does working together, as father and son, affect your relationship and the business?

D.F.: I think it’s a positive thing. People like to see families working together. I’ve always worked with my dad. It’s nice to be able to come in and be honest and work through (anything).

J.F.: He’s brought a lot of new things to the table; there’s no doubt about that. I’ve learned from some of his new electronic things and he’s learned some of the old ways of handling the job and the customer from me.

Question: To what do you attribute your nearly 50 years in business?

D.F.: Hard work and living within your means.

J.F.: Being honest and giving what the customer wants. Present new ideas, but not change the customer’s ideas.

Question: What makes your business unique?

J.F.: Our capabilities of designing unique items.

D.F.: We have the ability to prototype and have quick turnaround… And our workers are very knowledgeable. They have been around here for quite a while. They have the knowledge to be able to pinpoint a solution.

Question: What do you hope to see your business contribute to our community?

D.F.: I would love to have 40 people working on the floor. I would love to be a big employer in this town. The way I gauge my success is if that parking lot is full or not. That’s something I really enjoy; seeing my workers come in and know that is providing for them and their families. That’s also handed down to the next generation as well. (The children) can see their parents working and they can have that sense of ownership and pride within their community.

Question: What are your future goals for the business?

D.F.: To maintain our current reputation of our quality products and continue to be competitive in this ever-evolving world of manufacturing.

J.F.: I’d like to continue to reinvest and maintain our honesty. (I’d) also like to creep out into other ventures, but when we do that, we want to make sure we’re making smart choices. Be aggressive and smart.

Published: June 27, 2010

By, Shannon Maynard

Jackson Citizen Patriot