In the world of manufacturing, the ability to streamline production processes is crucial for success. One of the key tools that can aid in achieving this goal is prototyping, which allows manufacturers to refine their designs, optimize production workflows, and identify potential issues before full-scale production begins. Salco Engineering, with their expertise in design and prototyping, offers invaluable solutions for streamlining production. In this article, we will explore the benefits and techniques of streamlining production through proto services with Salco Engineering.

The Power of Prototyping

Prototyping serves as a bridge between design and production. It enables manufacturers to visualize their ideas, test functionalities, and gather valuable feedback from stakeholders. Salco Engineering understands the power of prototyping and its impact on production efficiency. By utilizing prototyping techniques, manufacturers can refine their designs, reduce errors, and make informed decisions that ultimately lead to improved production processes.

Early Detection of Design Flaws

One of the significant advantages of developing prototypes is the early detection of design flaws. By creating a physical prototype of a product, manufacturers can identify potential issues before mass production begins. Salco Engineering’s expertise in prototyping allows them to pinpoint design flaws, optimize product performance, and ensure that the final design meets the desired specifications. This early detection of flaws saves valuable time and resources that would otherwise be wasted on rework or recalls during production.

Iterative Refinement

Prototyping with Salco Engineering goes beyond a one-time validation process. They embrace an iterative approach to refinement. Through successive iterations, manufacturers can continuously improve their designs, making necessary adjustments and enhancements along the way. This iterative refinement process allows for a more efficient and streamlined production process, as the final design is based on valuable insights and real-world testing.

Optimizing Production Workflows

Streamlining production involves optimizing workflows to eliminate bottlenecks, reduce waste, and enhance efficiency. Salco Engineering understands the importance of integrating prototyping into production workflows to achieve these goals. By creating prototypes at various stages of the production process, manufacturers can identify potential inefficiencies and make necessary adjustments. Prototypes helps in determining the most efficient assembly methods, identifying optimal materials, and optimizing the use of resources.

Collaboration and Communication

Effective collaboration and communication between design and production teams are crucial for streamlining production. Salco Engineering facilitates this collaboration by providing tangible prototypes that serve as a common visual reference for all stakeholders. The physical prototype allows for clearer communication and shared understanding of the product’s design, features, and requirements. This collaborative approach helps in aligning the entire production team, minimizing errors, and fostering a smoother production process.

Cost and Time Savings

Prototyping with Salco Engineering brings significant cost and time savings to the production process. By identifying and resolving design flaws early on, manufacturers can avoid costly rework and production delays. The ability to optimize production workflows through prototyping also reduces production cycle times, resulting in faster time-to-market. Additionally, the iterative refinement process ensures that the final product is efficient, reliable, and meets customer expectations, reducing the risk of costly product recalls or customer dissatisfaction.

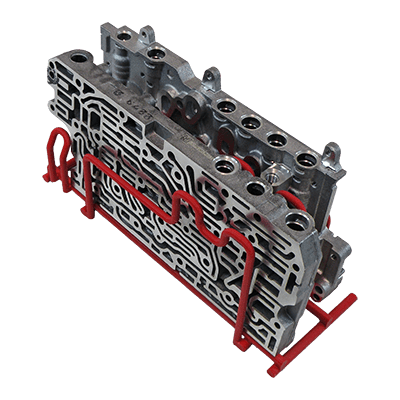

Prototyping Services at Salco

Streamlining production through prototyping is a powerful strategy for manufacturers aiming to enhance efficiency and optimize their production processes. Salco Engineering’s expertise in design and 3D printing offers invaluable solutions for achieving these goals. Through early detection of design flaws, iterative refinement, optimized production workflows, and enhanced collaboration, Salco Engineering helps manufacturers realize the benefits of prototyping.