In today’s competitive industrial landscape, precision manufacturing is the cornerstone of success for businesses across a variety of industries. Whether producing components for the automotive, aerospace, medical, or electronics sectors, precision and quality are critical. A reliable wire forming company can play a crucial role in achieving these standards. This article explores what to look for when choosing a wire forming company to ensure the highest levels of quality and precision manufacturing.

Understanding the Role of a Wire Forming Company in Precision Manufacturing

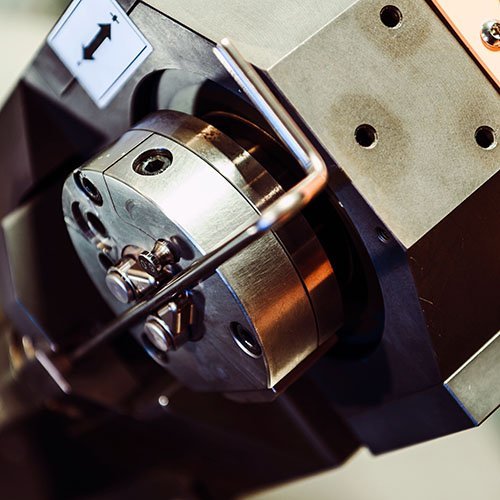

Wire forming involves transforming wire into custom shapes and components for a wide range of applications. From intricate medical device components to robust industrial equipment parts, wire forming companies bring designs to life with unparalleled accuracy and efficiency. These companies often employ advanced machinery like CNC wire bending and 3D forming equipment to meet tight tolerances and complex design specifications.

A wire forming company that specializes in precision manufacturing delivers more than just parts; it ensures consistency, durability, and optimal functionality. The right partner can help streamline production processes, reduce waste, and improve the overall quality of the final product.

Key Factors to Consider When Choosing a Wire Forming Company

1. Expertise in Precision Manufacturing

The first and foremost factor to consider is the company’s expertise in precision manufacturing. Not all wire forming companies are equipped to handle the intricate requirements of precision-driven industries. Look for companies with proven experience in working with tight tolerances and complex geometries. A portfolio of past projects in industries like aerospace, automotive, or medical can be a good indicator of their capabilities.

2. Advanced Technology and Equipment

State-of-the-art equipment is essential for achieving precision and consistency. A reputable wire forming company should utilize advanced technologies, such as CNC wire forming machines and automated bending systems. These machines not only ensure accuracy but also allow for greater flexibility in design and faster turnaround times.

For example, CNC wire forming enables the creation of intricate parts with exacting tolerances, which is critical for industries like healthcare and electronics. Additionally, companies that invest in the latest technology are better positioned to adapt to evolving industry demands.

3. Material Expertise

Wire forming requires expertise in handling a wide variety of materials, from stainless steel and aluminum to specialty alloys. The material choice can significantly impact the performance and durability of the finished product. A top-tier wire forming company will provide guidance on material selection based on your specific application and performance requirements.

For instance, stainless steel is often preferred for its corrosion resistance and strength, while aluminum may be chosen for its lightweight properties. An experienced company will have the capability to work with these and other materials, ensuring the final product meets your exact specifications.

4. Customization and Design Support

Every project has unique requirements, and a one-size-fits-all approach rarely works in precision manufacturing. The best wire forming companies offer customization options and design support to tailor their solutions to your needs.

From prototyping to production, a reliable company will work closely with you to refine designs, optimize manufacturing processes, and address potential challenges. Look for a partner that provides engineering expertise and collaborative design services to ensure the final product aligns with your goals.

5. Industry Experience and Reputation

The company’s experience and reputation in the industry can speak volumes about its reliability. Seek out testimonials, case studies, or client references to gauge their track record. A company that has successfully delivered wire forming solutions to leading organizations in precision-driven industries is more likely to meet your needs.

6. Scalability and Lead Times

As your business grows, your production needs may increase. Ensure that the wire forming company you choose has the capacity to scale up production without compromising on quality or lead times. Companies with flexible manufacturing processes and efficient supply chain management can adapt to changing demands, ensuring you meet your deadlines and maintain operational efficiency.

The Benefits of Choosing the Right Wire Forming Company

Selecting the right wire forming company offers numerous benefits, including:

- Improved Product Quality: High-precision components that meet exact specifications ensure optimal performance.

- Cost Savings: Streamlined production processes and reduced waste contribute to lower overall costs.

- Faster Time-to-Market: Advanced technology and efficient workflows allow for quicker production and delivery.

- Enhanced Reputation: Superior product quality strengthens your brand and builds customer trust.

Why Choose Salco Engineering for Precision Manufacturing?

At Salco Engineering, we pride ourselves on being a trusted partner for businesses seeking high-quality wire forming solutions. With decades of experience in precision manufacturing, we offer:

- State-of-the-Art Equipment: Our CNC wire forming machines deliver unparalleled accuracy and consistency.

- Material Expertise: We work with a wide range of materials, including stainless steel, carbon steel, and specialty alloys.

- Custom Solutions: From prototyping to production, we tailor our services to meet your specific needs.

- Rigorous Quality Assurance: Our ISO-certified processes ensure that every component meets the highest standards of quality and reliability.

- Industry Experience: We serve a diverse range of sectors, including automotive, aerospace, medical, and more.

Conclusion

Choosing the right wire forming company is a critical decision that can significantly impact the success of your precision manufacturing projects. By prioritizing factors such as expertise, technology, material handling, and quality assurance, you can find a partner that meets your needs and exceeds your expectations.

If you’re ready to take your manufacturing processes to the next level, consider partnering with Salco Engineering. Contact us today to learn more about our wire forming services and how we can help bring your designs to life with precision and quality.